Your napkin holder shouldn’t just hide in plain sight—it should spark compliments every time guests reach for a linen square. Learning how to make a napkin holder transforms basic lumber into a functional art piece that reflects your personal style, whether you’re crafting a rustic pine dispenser for farmhouse tables or a sleek geometric design for modern kitchens. Forget flimsy store-bought versions that tip over with a single pull; this guide delivers a rock-solid, custom-fit solution using straightforward woodworking techniques. You’ll master precise slot cutting, invisible joinery, and professional finishes that turn $20 worth of materials into a conversation-starting heirloom piece.

Essential Materials and Tools

Required Lumber and Hardware

Grab 24 inches of 1×4 pine board (¾” × 3½”) for the main body and 18 inches of 1×2 strip (¾” × 1½”) for base support—ideal for beginners due to affordable cost and easy sanding. For premium projects, upgrade to ½” × 4″ oak (20″ length) to showcase dramatic grain patterns after finishing. You’ll also need #6 × 1¼” wood screws (8 pieces), water-resistant wood glue, and sandpaper progressing from 120-grit (for rough shaping) to 320-grit (for silky-smooth finishes). Don’t skip wood filler—it’s essential for hiding joint gaps in soft pine.

Must-Have Workshop Tools

A miter saw cuts crisp 90° angles for side panels in seconds, while a power drill with 1/8″ pilot bit prevents splitting during assembly. An orbital sander is non-negotiable for achieving finish-ready surfaces—skip hand-sanding to avoid visible scratches. Secure pieces with four 24″ bar clamps during glue-ups, and always wear safety glasses when cutting or sanding. Pro tip: Use a countersink bit to recess screw heads flush with the wood surface, creating invisible fastening points that elevate your craftsmanship.

Design Options for Every Style

Classic Vertical Dispenser Build

This 6″ tall × 5½” wide workhorse holds standard 6½” napkins with a 15° tilted front face for effortless single-napkin extraction. The secret to stability? A 2″ thick weighted base that resists tipping during use. Cut your front panel with a 15° bevel on the miter saw, then drill 1/8″ pilot holes at slot ends before jigsawing a ⅛” × 4″ opening—this prevents wood tear-out. Add a removable top panel for quick refills, and consider an optional ⅛” acrylic window to monitor napkin levels without lifting the cover.

Horizontal Trough Construction

Perfect for crowded countertops, this 7″ long × 4″ wide trough compresses napkins via 5° tapered sides, eliminating frustrating refolds. Round interior corners with a ¼” radius router bit for effortless cleaning, and rout a ⅛” deep recessed bottom to catch crumbs and spills. For cocktail napkin versatility, install a removable divider cut from ¼” plywood. The tapered design means napkins self-adjust as the stack depletes—no more wrestling with stubborn top sheets.

Step-by-Step Building Process

:max_bytes(150000):strip_icc()/38619-215b552f37314d8d9dff5a93686aba84.jpg)

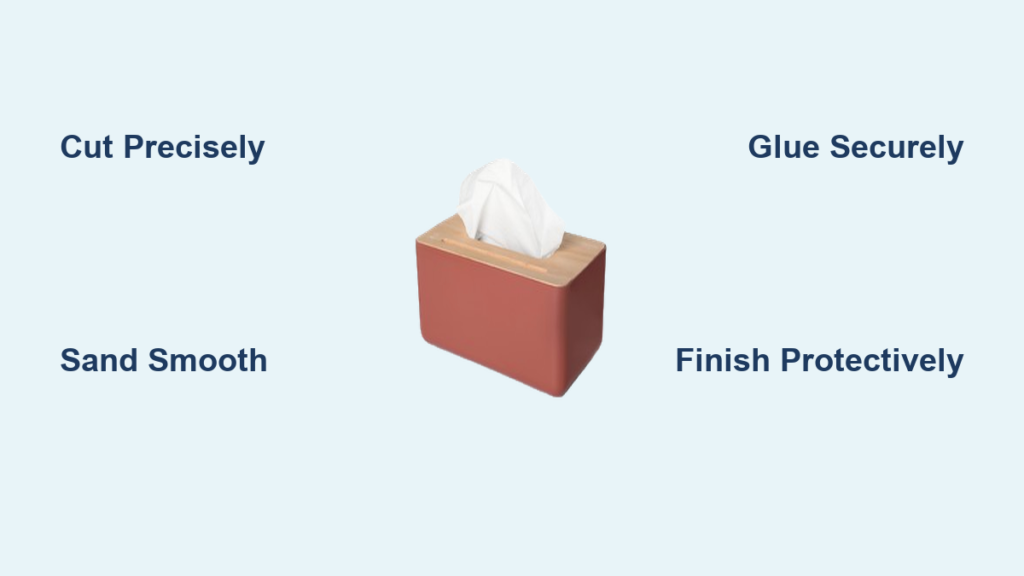

Cut Your Pieces Precisely

Start with accurate cuts: Back panel (6″ × 5½”), two side panels (6″ × 3½”), base (5½” × 3½”), and front panel (3½” × 5½” with 15° bevel). Mark all pieces with pencil and straightedge first—measure twice, cut once. For horizontal troughs, cut side pieces at 5° angles using your miter saw’s tilt function. Always cut slots after main assembly; drilling 1/8″ pilot holes at both ends prevents splintering when jigsawing the 4″ slot.

Create the Napkin Slot

Position the slot 2″ from the top center of your front panel—too low causes jams, too high reduces capacity. Drill 1/8″ starter holes at slot endpoints, then connect them with a jigsaw using slow, steady strokes. Immediately smooth edges by wrapping 220-grit sandpaper around a ½” dowel; rough slots snag linen fibers, causing frustrating rips. Test with an actual napkin before final assembly—adjust slot width if napkins bind.

Shape and Smooth Components

Round bottom edges with a 1/8″ radius bit for comfort and visual softness, then chamfer top surfaces 1/16″ to eliminate sharp corners. Sand progressively: 120-grit removes saw marks, 220-grit erases scratches, and 320-grit preps for flawless finishing. Vacuum between grits—embedded dust particles ruin smooth finishes. For geometric designs, use a biscuit joiner to align 45° mitered corners perfectly before gluing.

Assembly Techniques That Last

Dry Fit Before Gluing

Assemble all pieces without glue first. Check squareness by measuring diagonal corners—if measurements differ, joints won’t align. Verify slot positioning by sliding in a napkin stack; misalignment causes constant refills. Mark problem areas with pencil for adjustment. This 5-minute step prevents irreversible glue mistakes that waste hours of work.

Glue and Clamp Properly

Apply glue in thin, even beads—excess squeezes out and creates messy seams. Assemble pieces in this order: sides to base, then back panel, then front. Use bar clamps with protective wood pads to avoid marring surfaces. Tighten clamps to “hand-tight plus a quarter turn”; over-tightening starves joints of glue. Wipe excess immediately with a damp cloth before it dries.

Reinforce Critical Joints

Counterbore screw holes 3/8″ wide × ¼” deep, then drive screws at 15° angles into end grain for maximum hold. Fill holes with matching wood plugs sanded flush after curing—this creates invisible reinforcement. For horizontal troughs, use pocket screws from the base upward to hide fasteners completely.

Professional Finishing Methods

Sand to Perfection

Sand only with the wood grain direction—cross-grain scratches telegraph through finishes. Progress through grits without skipping steps; jumping from 120 to 320 leaves visible marks. Vacuum dust after each grit, then wipe with a tack cloth. Test sanding quality by running your palm over the surface—it should feel like glass.

Choose Your Stain Strategy

Pine requires pre-stain conditioner to prevent blotchiness; skip this and you’ll get splotchy, uneven color. Apply oil-based stain with a foam brush along the grain, waiting 5 minutes before wiping excess. Water-based finishes need grain-raising: Dampen wood with a cloth, let dry, then lightly sand with 320-grit before applying. Always test stains on scrap pieces first.

Apply Protective Coating

Opt for satin water-based polyurethane—four thin coats with 2-hour drying intervals between. It dries crystal clear (unlike yellowing oil-based) and resists napkin moisture. Brush in long, unidirectional strokes, then lightly sand with 400-grit between coats. The final coat cures in 24 hours—resist using it sooner to avoid sticky residue.

Troubleshooting Common Problems

Fix Gaps and Splits

Gaps from inaccurate cuts? Fill with wood putty tinted to match your stain, then sand flush. Prevent splits by drilling pilot holes 90% of screw diameter—e.g., 3/32″ hole for #6 screws. If wood cracks during assembly, inject glue into the split with a syringe, clamp tightly, and wipe excess before it hardens.

Eliminate Finish Flaws

Blotchy stain? Sand back to bare wood, apply pre-stain conditioner, and restart. Dust specks in finish? Sand lightly with 400-grit, wipe with mineral spirits, and recoat in a dust-free environment. Always finish in a room above 65°F with low humidity for optimal results.

Maintenance and Longevity Tips

Regular Care Routine

Dust weekly with a microfiber cloth—never use abrasive cleaners that strip finishes. Wipe spills immediately with a damp (not wet) cloth to prevent water rings. Reapply a thin coat of Danish oil annually to maintain moisture resistance, especially for pine holders.

Seasonal Adjustments

Wood expands in summer humidity and contracts in winter dryness. Check screw tightness quarterly; loose hardware causes wobbling. Store holders away from radiators or windows—direct heat warps wood within weeks. For outdoor use, apply marine-grade spar urethane for UV and moisture protection.

Design Variations and Upgrades

Cocktail Napkin Version

Scale down all dimensions by 30% for 3½” × 3½” × 2″ internal space. Add a ¼” steel plate under the top panel for weight, and line the base with non-slip silicone matting. This compact version fits bar carts and patio tables without cluttering surfaces.

Expand to Paper Towel Holder

Triple vertical dispenser dimensions, then drill 1″ diameter holes through side panels for a dowel rod. Insert a 12″ wooden dowel to hold standard rolls, and add a tension spring (from hardware store) to control dispensing speed. Mount to walls using a French cleat for space-saving kitchen organization.

Budget and Timeline Planning

Cost Breakdown by Material

Basic pine holders cost $16–25 total (lumber $8–12, hardware $3–5, finish $5–8). Hardwood versions using oak or maple run $43–62 but deliver decades of use. Pro tip: Buy finish supplies in bulk—they cover 5+ projects and cut per-unit costs by 60%.

Time Investment Guide

First-timers complete pine holders in 8 active hours: 1 hour planning, 2 hours cutting, 3 hours assembly, 2 hours finishing. Hardwood projects with complex joinery take 13–19 hours but showcase advanced skills. Rushing drying times causes sticky finishes—build in 24-hour cure periods.

Your handmade napkin holder becomes a daily testament to craftsmanship—no two look alike. Start with pine to master fundamentals, then graduate to hardwoods with hidden magnets or LED accents. Remember: Measure slots twice, sand relentlessly, and never skip the dry fit. In less time than it takes to watch a movie, you’ll create a piece that elevates every meal from ordinary to exceptional.