Tired of flimsy plastic badge holders that crack after a month? You’re not alone—nearly 70% of professionals replace their ID holders quarterly due to wear and tear. Learning how to make a badge holder solves this frustration permanently. This guide transforms basic fabric scraps into a durable, custom ID solution that withstands daily use while reflecting your personal style. Forget expensive store-bought versions; with just quilting cotton, interfacing, and clear vinyl, you’ll create a badge holder that survives coffee spills, pocket friction, and constant scanning. In this 45-minute project, you’ll master professional techniques like mitered corners, vinyl window installation, and stress-point reinforcement—skills that turn a simple DIY task into a polished accessory for work, school, or conferences.

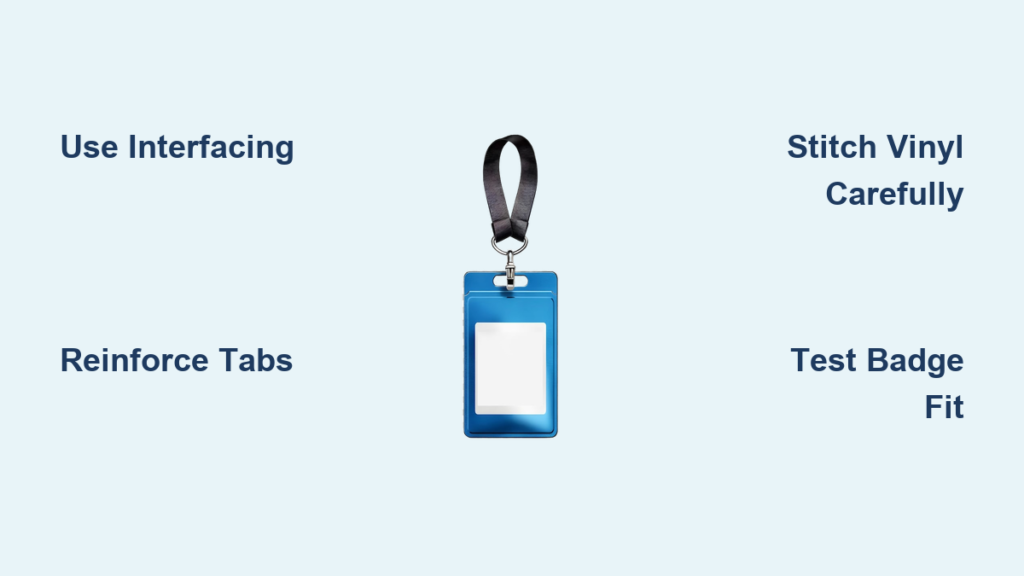

Unlike mass-produced alternatives, your handmade badge holder accommodates both horizontal and vertical IDs while maintaining a sleek profile. The clear vinyl window allows instant scanning without removal, and the split-ring attachment works with lanyards, belt loops, or retractable reels. Most importantly, you control every detail—from fabric patterns matching your work wardrobe to reinforced stitching that prevents common failure points. Ready to stop replacing cheap holders? Let’s dive into the exact supplies and steps for creating a badge holder that outlasts store-bought versions.

Gather Badge Holder Supplies in Under 5 Minutes

Skip the hardware store run—everything you need fits in your sewing kit. For the full badge holder and lanyard set, grab a 3.75″ × 44″ quilting cotton strip (standard width), Pellon Peltex interfacing (¼ yard), and a vinyl scrap larger than 3.5″. Essential hardware includes one 1-inch swivel hook and a 20mm split ring. Don’t forget your glue stick for temporary basting—it’s the secret to crisp folds without stiff residue.

Critical Supply Checklist:

– Quilting cotton (pre-washed to prevent shrinkage)

– Pellon Peltex Two-Sided Extra Firm Stabilizer

– Clear vinyl (12-14 gauge thickness)

– 20mm split ring + 1-inch swivel hook

– Teflon sewing foot (or tissue paper substitute)

– Glue stick (for temporary holds only)

Avoid common mistakes like using thin cotton or skipping interfacing—these cause sagging and premature wear. If making just the badge holder, reduce fabric to large scraps but keep all interfacing and hardware. Pro tip: Test vinyl scraps by bending them; if they crack, replace with thicker material for durability.

Why Vinyl Thickness Matters for Scanning

Thinner vinyl (<10 gauge) warps during sewing, creating bubbles that block ID scanners. Thicker vinyl (>16 gauge) becomes rigid and cracks at folds. The 12-14 gauge sweet spot maintains flexibility while resisting scratches. When centering your vinyl behind the frame opening, ensure ⅛” overlap around all edges—this prevents shifting during stitching and guarantees full scanning visibility.

Create Unravel-Proof Lanyard Edges

Your lanyard’s longevity depends entirely on this folding sequence. Start with the 3.75″ × 44″ fabric strip wrong sides together, pressing a sharp center crease. Open it flat, then fold each long edge to meet that center line. Fold once more along the original crease—this fully encases raw edges before stitching.

Stitch Lanyard Seams Without Twisting

Sew both long edges ⅛” from the folded edge using a straight stitch. Keep tension moderate (3.0-3.5 on most machines) to avoid puckering. When threading the swivel hook, position it 2″ from one end before overlapping the strap ends. Crucially, align the overlapping ends with right sides out—this hides the seam inside when turned. Backstitch 4-5 times across the overlap for security, then slide the hook to cover the seam before turning. Finish with a horizontal bar tack ½” below the hook to prevent rotation.

Install Split Ring for Secure Badge Attachment

The attachment tab is your badge holder’s weakest point if done poorly. Cut a 1.5″ × 4″ fabric scrap, fold lengthwise wrong sides together, and press. Fold short ends toward center, then fold in half again. Stitch both long edges ⅛” from the edge to create a ½” wide tab. Thread your split ring through this tab immediately after stitching—it’s impossible once fused to the badge back.

Position Tab for Maximum Durability

Center the tab on the badge back’s top edge with raw ends facing downward. Sew it in place with a ¼” seam allowance, backstitching at both ends. The downward orientation directs pull force along the seam rather than against it—this simple trick prevents tabs from ripping off after months of use. Test ring movement before final assembly; if stiff, reposition the tab slightly.

Build Vinyl Window Frame Without Wrinkles

This is where most DIY badge holders fail. Place Pellon Peltex on the wrong side of your front fabric piece, centered over the window area. Do not fuse yet—use a glue stick for temporary hold. Cut diagonal slits from each inside corner of the interfacing hole to the fabric corners. These flaps wrap neatly around edges for crisp corners.

Wrap Fabric Corners Like a Tailor

Fold the inner flaps over the interfacing edges, securing with glue stick. For outer corners, fold diagonally over interfacing corners to create mitered points—this eliminates bulk. Fold long edges over, pressing each section before gluing. Only then cover with a pressing cloth and fuse per manufacturer instructions. Skipping the pressing cloth risks melted interfacing on your iron—a costly mistake.

Sew Vinyl Window Without Skipped Stitches

Place vinyl centered behind the frame opening, clipping it in place from the fabric side. Always sew with the fabric facing up—the vinyl sticks to presser feet when underneath. Use a Teflon foot if available, or place tissue paper between vinyl and foot (tear away after sewing). Stitch ⅛” from the opening edge with a 2.5mm stitch length.

Reinforce Top Edge Against Pull Damage

Add one extra straight stitch across the top edge only—this critical reinforcement prevents tearing when badges are inserted or removed. Never stitch the entire perimeter twice; it creates bulky seams that hinder badge insertion. After sewing, trim thread tails close to fabric to avoid snagging.

Construct Badge Back With Stress-Point Protection

Glue Pellon Peltex to the back fabric’s wrong side, positioned ⅜” from the top edge and centered horizontally. Fold top corners diagonally over interfacing corners, then fold the top edge down over interfacing. Secure with glue stick—do not fuse until after tab attachment. Fold side edges to match interfacing width, then fold the bottom edge up and over.

Fuse Layers Without Melting Vinyl

Tuck the top edge under for a clean finish before fusing. Use a pressing cloth and apply heat for only 8-10 seconds per section—excessive heat warps vinyl in adjacent pieces. After fusing, topstitch across the top edge ⅛” from the fold to lock all layers. This stitching anchors the interfacing against pulling forces.

Complete Final Assembly in 3 Steps

Place front and back pieces together wrong sides facing—this puts both finished surfaces outward. Clip sides and bottom, leaving the top open for badge insertion. Sew around the perimeter with a ⅛” seam allowance using backstitches at start and end. Trim seam allowances to ⅛” to reduce bulk, especially at corners.

Test Badge Fit Before Final Stitching

Insert a standard 3.375″ × 2.125″ ID card before sewing the final seam. If tight, trim ⅛” from the window opening edges. The card should slide in smoothly but not rattle—ideal clearance is 1/16″ on all sides. After sewing, gently pull the badge through the top opening to ensure no threads obstruct insertion.

Fix Common DIY Badge Holder Failures

Problem: Vinyl bubbles after sewing

Solution: Reduce presser foot pressure and use tissue paper barrier. Never stretch vinyl while sewing—it must lie flat under natural tension.

Problem: Lanyard seam unravels

Solution: Increase backstitch count to 6-7 passes and use all-purpose thread (not embroidery thread). The bar tack must anchor through all strap layers.

Problem: Split ring sticks

Solution: Position the tab ¼” below the top edge to prevent ring contact with fused interfacing. Test ring movement before fusing the badge back.

Customize Your Badge Holder With Style

Coordinate lanyard and badge holder fabrics for a unified look—stripes with solids, or matching patterns in complementary colors. Add personality with contrasting topstitching thread (try navy on cream fabric). For healthcare workers, embroider your name on the tab before assembly; the interfacing stabilizes stitches.

Optimize for Your Work Environment

- Hospital settings: Use antimicrobial fabric and add a second split ring for backup badge attachment

- Schools: Choose bright patterns kids love, with extra topstitching for playground durability

- Corporate offices: Opt for subtle pinstripes with metallic thread accents

Maintain Your Handmade Badge Holder for Years

Spot clean with a damp cloth and mild soap—never machine wash. Air dry completely before reinserting your badge; trapped moisture warps interfacing. Every three months, check stress points: the tab attachment and lanyard hook seam. Reinforce with a few hand stitches if threads loosen. When pressing, avoid vinyl areas entirely—use steam only on fabric sections.

Your custom badge holder outperforms plastic alternatives by design: the Pellon Peltex interfacing maintains rigidity without cracking, while the fabric exterior resists scratches that obscure store-bought holders. Most importantly, you’ve created a solution tailored to your exact needs—whether it’s accommodating a thick security badge or matching company colors. This isn’t just a DIY project; it’s a permanent fix for a daily frustration that costs professionals hundreds in replacements annually. Now that you know how to make a badge holder, you’ll never settle for flimsy plastic again. Keep your scraps handy—you’ll want to make extras for colleagues once they see your durable, stylish creation.