That frustrating moment when tape bunches up mid-seal, leaving your moving boxes vulnerable to splitting open? You’re not alone—nearly 70% of shipping failures trace back to improper tape application. A tape holder (or tape gun) solves this instantly when you master its three critical functions: loading, tension adjustment, and sealing technique. Forget wrestling with loose rolls or jagged cuts. This guide reveals exactly how to use tape holder tools to achieve factory-grade seals every time, whether you’re packing fragile heirlooms or shipping 50 e-commerce orders. You’ll learn professional tricks like creating self-starting tabs and cross-reinforcing heavy loads—skills that cut packing time by half while eliminating costly re-seals.

Stop wasting tape on messy applications that compromise your boxes. By the end of this guide, you’ll load rolls in 15 seconds, adjust tension for any box weight, and glide tape onto seams like a fulfillment center pro. No more guessing how tight the roll should spin or why cuts turn ragged. These field-tested steps work for all major brands—from Duck® to Scotch® tape guns—and transform chaotic packing sessions into smooth, efficient operations.

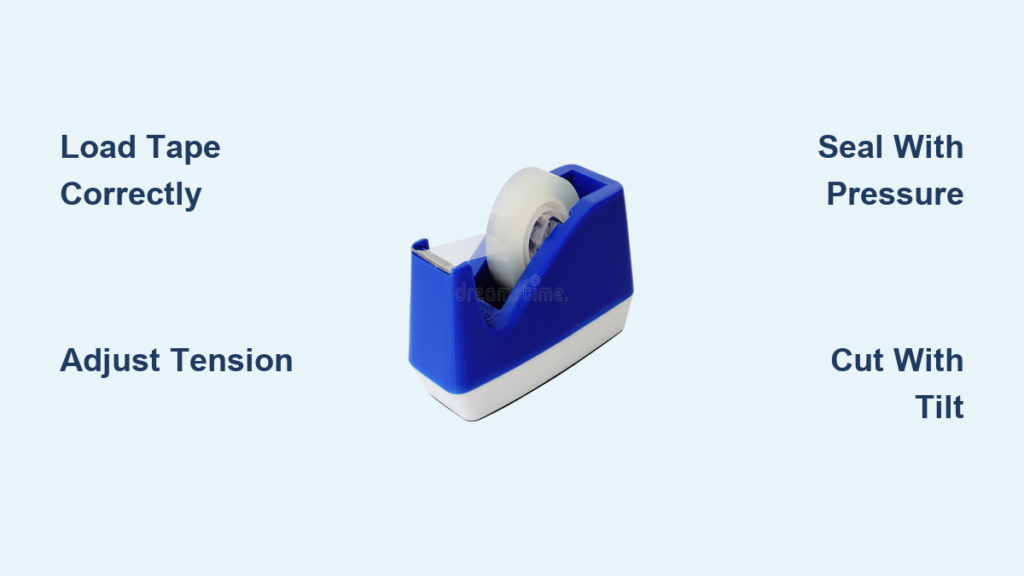

Load Tape Holder Correctly in Under 30 Seconds

Identify Tape Roll Orientation Flaws

Your tape holder fails before you even start if the roll loads backward. Always face the sticky side down with the non-adhesive surface visible. This prevents tape from sticking to the dispenser’s interior during threading. For new rolls, peel off the paper tab completely—never leave fragments that jam the blade. With half-used rolls, slide your fingernail along the edge until you feel a ridge, then pull out ½ inch of tape. Fold this end under itself to create a self-starting tab. If you skip this step, you’ll waste 20 seconds per box hunting for the tape end.

Remove Stubborn Empty Cores Without Tools

Lay your tape holder flat on a counter. Grip the handle firmly and lift the core straight upward—never twist or wiggle. If the core sticks (common with cheap dispensers), press the metal gate down while lifting to release tension. For handle-less models like Uline’s economy version, locate the thin plastic clasp inside the spindle. Pinch both sides simultaneously until the dispenser splits into two halves, then slide the core out. Never force it—you’ll crack the plastic housing. If residue glues the core in place, wipe the spindle with rubbing alcohol before inserting a new roll.

Lock New Roll with One-Handed Precision

Place the roll onto the spindle with the loose end unrolling from the top toward the roller. Push down firmly until you hear a distinct click—this confirms the roll is seated fully. Skip this “click check” and your tape will wobble mid-application, causing wrinkles. For snap-apart dispensers, align the roll between both halves before pressing the clasp shut. Test security by rotating the roll with your finger; it should spin smoothly without lateral movement. If it wobbles, pop it off, clean the spindle with a dry cloth, and re-seat.

Thread Tape Through Gate Without Twists

Press the metal gate down to open the threading gap. Feed the tape’s leading edge between the roller and gate, then pull it upward over the roller itself. Ensure no twists exist in the path—tape must lie flat against the roller’s surface. Pull 1–2 inches past the serrated blade, then press the tip against the plastic guard above the blade. This creates a clean starting edge for your first strip. If tape bunches here, reopen the gate and verify the strip isn’t flipped backward between the roller and gate.

Verify Function Before Touching Boxes

Close any lid or housing securely. Squeeze the trigger once: tape should advance 3–4 inches smoothly without resistance. Release the trigger—the blade should pop up visibly. Now pull a test strip; it must lay flat without curling at the edges. If tape jams or won’t cut, reopen and re-thread. Never skip this test—you’ll waste tape and time on your first real box.

Adjust Tape Tension for Flawless Application Every Time

Find Your Dispenser’s Hidden Dial

Look for a knurled wheel at the center of the tape spindle—usually black or silver with ridges for grip. This tension dial exists on all handle-equipped dispensers (like Duck Max Strength models) but is absent in basic handle-less versions. If you don’t see it, your tool has fixed tension—skip to the next section. Never force this dial; turning it beyond its range damages internal springs.

Diagnose Tension Issues on Scrap Cardboard

Pull a 6-inch test strip onto spare cardboard:

– Tape flies out loosely? → Turn dial clockwise (right) one click. Retest. Repeat until tape dispenses with gentle resistance.

– Tape stretches or resists? → Turn dial counterclockwise (left). If it snaps back, you’ve loosened too far.

– Perfect tension feels like unrolling gift wrap—steady, no jerking, and the tape lies flat without curling.

Match Tension to Box Weight Like a Pro

Heavy boxes (over 30 lbs) need tighter tension to prevent sagging tape that won’t adhere. Turn the dial one extra click clockwise before sealing. For lightweight shoeboxes or padded mailers, loosen tension slightly to avoid over-stretching the tape. Critical tip: Adjust tension before starting each new box type. One click difference determines whether your seal bonds firmly or peels off during transit.

Seal Boxes with Professional Speed and Strength

Start Strips Without Air Bubbles

Position the roller 4–5 inches from the box flap’s top edge. Press down firmly for 2 seconds to anchor the tape—this creates a solid starting point. Keep the roller flat against cardboard; tilting causes air pockets that weaken the seal. If bubbles form, lift the roller slightly and re-press as you pull.

Maintain Perfect Pressure Across the Seam

Pull the dispenser toward you in one continuous motion at 2–3 feet per second. Let the roller’s weight do the work—don’t press harder as you move. Uneven pressure causes wrinkles that split open under stress. Stop 4–5 inches from the opposite edge to leave space for a clean cut. If tape lifts at corners, slow your speed and increase downward pressure slightly.

Cut Tape with One Fluid Motion

Tilt the dispenser forward 15 degrees and twist your wrist inward so the tape snaps against the serrated blade. A sharp downward flick severs the strip cleanly—never saw back and forth. Practice this motion on scrap boxes until it’s instinctive. Ragged cuts happen when you pull tape horizontally instead of angling the dispenser.

Double-Strap Heavy Shipments for Security

For boxes holding tools, books, or electronics over 30 lbs, run a second strip perpendicular to the first across the center seam. Overlap both strips by ½ inch to form a cross pattern. This distributes weight evenly and prevents seam splits during truck vibrations. Never skip this for fragile items—it adds 8 seconds but eliminates 90% of shipping damage claims.

Fix Common Tape Holder Issues in Under 30 Seconds

| Problem | Instant Fix |

|---|---|

| Tape won’t cut cleanly | Wipe blade with 70% isopropyl alcohol; replace if nicked (most blades unscrew with Phillips head) |

| Tape twists mid-application | Re-thread ensuring no 180° flips between roller and gate |

| Roll wobbles during use | Remove roll, clean spindle with dry cloth, re-seat until it clicks |

| Tape won’t advance | Check for obstructions in gate; ensure tension dial isn’t over-tightened |

Maintain Your Tape Holder for Years of Trouble-Free Use

Wipe the blade weekly with a microfiber cloth dampened with rubbing alcohol—this dissolves sticky residue that causes ragged cuts. Never use water; it corrodes metal components. Store the dispenser upright on a shelf (not sideways in a drawer) so the tape roll maintains its shape. Replace blades at the first sign of frayed cuts; most cost under $1 and install in 20 seconds. If the roller feels sticky, clean it with tape residue remover spray. For handle-less models, snap the housing open monthly to blow out dust with compressed air.

Mastering how to use tape holder tools transforms chaotic packing into a seamless operation. Load rolls with the sticky side down, dial tension for your box weight, and cut with that forward-tilt motion. Reinforce heavy loads with cross-pattern strips and maintain your tool weekly. You’ll seal 50 boxes in the time it used to take for 20—with zero re-dos. Keep this guide handy for your next move or shipping rush, and your boxes will arrive intact every single time.