That stubborn battery compartment door won’t close properly, or your device keeps losing power intermittently. Nine times out of ten, the culprit is a worn or damaged battery holder spring. These small metal components endure constant pressure and corrosion, eventually losing their tension or breaking entirely. The good news? Most battery spring problems are surprisingly simple to diagnose and repair with basic household tools.

You’ve probably experienced this frustration: your TV remote stops working mid-show, your flashlight dies unexpectedly during a power outage, or your child’s toy suddenly goes silent. Before you replace the entire device, take a moment to inspect the battery compartment. This comprehensive guide walks you through identifying spring issues, sourcing replacement parts, and executing professional-quality repairs. Whether you’re dealing with a remote control, flashlight, or electronic device, these proven techniques will restore reliable battery contact within minutes.

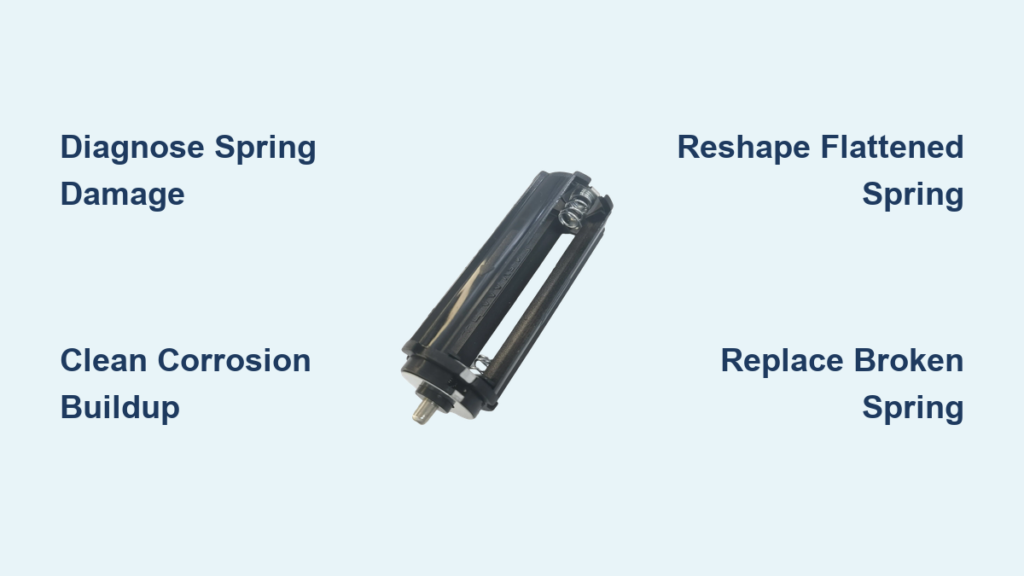

Diagnose Battery Spring Failure Symptoms Before Repair

Loose battery compartments create frustrating power interruptions that mimic dead batteries. Intermittent device operation often indicates spring tension loss, where batteries shift position and break electrical contact when you move the device. Corrosion buildup appears as white, green, or blue deposits on the spring surface, creating resistance that blocks electrical flow. Don’t mistake these symptoms for battery failure—they’re clear signs you need to fix battery holder spring problems.

Physical inspection reveals critical clues about spring condition. Bent or flattened springs appear compressed against the compartment wall with little resilience. Broken or detached springs may rattle inside the compartment or be completely missing. Rust formation compromises conductivity and weakens the metal structure over time. Proper diagnosis prevents unnecessary battery replacements and wasted money.

Test Battery Contact Pressure Effectively

Remove batteries and examine the spring’s shape with a flashlight. Healthy springs maintain a curved or coiled profile that springs back when pressed. Flattened springs appear compressed against the compartment wall with little resilience. Test tension by gently pressing the spring—it should return to position immediately with noticeable resistance. If it feels mushy or doesn’t spring back, you’ve confirmed your need to fix battery holder spring tension issues.

Check for Hidden Damage That Causes Intermittent Failures

Look inside the battery compartment using a flashlight at different angles. Hairline cracks in the spring metal often occur near attachment points and cause intermittent power loss. Solder joint failure appears as dark, grainy connections where the spring meets the circuit board, creating high resistance. Missing plating exposes raw metal to accelerated corrosion and eventual failure. These subtle issues often go unnoticed but significantly impact device reliability.

Gather Essential Repair Tools for Spring Restoration

Successful spring repair requires minimal tools, most already in your home. Needle-nose pliers provide precise grip for bending and positioning small springs without damaging surrounding components. Small flathead screwdriver helps pry corroded components without scratching plastic compartments. Fine-grit sandpaper (400-600 grit) removes corrosion and restores conductivity without damaging delicate spring surfaces.

Electrical contact cleaner or 90%+ isopropyl alcohol eliminates corrosion residue safely. Soldering iron (25-40 watts) handles reattachment of broken springs without overheating sensitive electronics. Flux-core solder ensures strong electrical connections that won’t break under spring tension. Replacement springs from donor electronics or hardware stores match most applications when permanent repair is needed.

Source Quality Replacement Springs for Permanent Fixes

Salvage compatible springs from old remote controls, broken toys, or discarded electronics that use the same battery size. Hardware stores stock compression springs in various sizes for universal applications—bring your damaged spring for comparison. Electronic component suppliers offer precision springs designed specifically for battery compartments when exact replacement is critical.

Clean Corroded Spring Contacts to Restore Power Flow

Corrosion creates resistance that blocks electrical flow, causing devices to behave as if batteries are dead. Begin by removing all batteries and photographing the compartment layout for reference. Brush loose corrosion using an old toothbrush or cotton swab dipped in vinegar or lemon juice. This simple step often resolves 70% of what seems like battery holder spring failure.

Remove Stubborn Buildup Without Damaging Components

For heavy corrosion, soak the affected area in white vinegar for 10-15 minutes to dissolve mineral deposits. Gently scrub with a fiberglass brush or fine steel wool, applying minimal pressure to avoid scratching. Rinse thoroughly with isopropyl alcohol and dry completely with compressed air or a hair dryer on cool setting—never use heat that could melt plastic components.

Restore Conductive Surface for Reliable Electrical Contact

Polish the spring using 400-grit sandpaper until bright metal appears, then progress to 600-grit for smoothness. Clean with alcohol to remove metal particles and oils that could cause future corrosion. Apply a thin coat of dielectric grease to prevent future corrosion without impeding conductivity—this crucial step extends spring life significantly.

Reshape Weak or Flattened Springs Without Breaking Them

Lost spring tension often results from metal fatigue or improper battery insertion. Assess the damage by comparing the spring’s curvature to a similar intact spring or reference image. Gradually reshape using needle-nose pliers, working in small increments to avoid metal fracture—bend just 5-10 degrees at a time with frequent tension tests.

Restore Proper Tension Through Controlled Bending

Grip the spring near its base and bend gently outward to increase curvature, always bending away from attachment points to avoid stress fractures. Test frequently by inserting a battery and checking contact pressure—proper tension should hold the battery firmly but allow easy removal. Avoid over-bending which can cause the spring to snap or lose its temper, requiring complete replacement.

Replace Broken or Missing Springs Permanently

When springs break or detach completely, replacement becomes necessary. Measure the original spring dimensions precisely: wire diameter, coil diameter, and free length using calipers if available. Match specifications from salvaged parts or universal spring assortments—most AA/AAA compartments use 0.3-0.5mm wire diameter springs.

Remove Old Spring Remnants Safely

Desolder broken spring pieces using a soldering iron and desoldering braid to clean attachment points thoroughly. Clean the attachment pad with isopropyl alcohol to ensure proper electrical connection. Test continuity between the pad and device circuitry using a multimeter before installing the new spring—this verifies you’re fixing the actual problem.

Install New Spring Securely for Long-Term Reliability

Position the replacement spring matching the original orientation exactly—reversed springs cause improper contact. Solder the connection using flux-core solder, ensuring full pad coverage without creating solder bridges. Test mechanical strength by gently tugging the spring before reassembly—proper solder joints should withstand moderate pressure.

Implement Quick DIY Spring Repair Hacks for Emergencies

When replacement parts aren’t immediately available, temporary fixes restore function until proper repair. Copper foil shim wrapped around a flattened spring increases thickness and tension immediately. Bent paperclip can substitute for completely missing springs in low-current applications like remotes—file sharp edges to prevent battery damage.

Household Material Solutions for Immediate Relief

Aluminum can shim stock cut to size provides excellent conductivity and spring properties for most household devices. Steel guitar string sections work as tension springs for larger battery compartments in flashlights or toys. Copper braid from speaker wire offers flexible, conductive replacement material that conforms to irregular shapes.

Prevent Future Spring Problems Through Smart Maintenance

Proper battery insertion and storage significantly extends spring life. Insert batteries gently without forcing or twisting, which damages springs over time. Remove batteries from devices stored longer than one month to prevent leakage damage—this simple habit prevents 80% of spring failures.

Regular Maintenance Routine for Long-Term Reliability

Inspect battery compartments quarterly for early corrosion signs before they become serious problems. Clean contacts with alcohol wipes during battery changes to maintain optimal conductivity. Store devices in dry environments with desiccant packets to reduce moisture exposure that accelerates corrosion.

Test Your Repair Success Before Declaring Victory

Thorough testing ensures lasting results and prevents repeat failures. Install fresh batteries and verify the compartment closes securely without excessive force. Power cycle the device multiple times, checking for consistent operation through several on/off cycles. Gently shake the device while powered to test contact stability under movement.

Performance Verification for Complete Confidence

Monitor operation over 24-48 hours for intermittent issues that might not appear immediately. Check battery voltage after extended use—stable readings confirm good spring contact without resistance. Compare device performance to pre-repair baseline to ensure full functionality has been restored.

Battery holder springs may be small, but their impact on device reliability is enormous. These straightforward repair techniques restore proper function to everything from television remotes to emergency flashlights in under 10 minutes. Regular maintenance prevents most spring failures, while the repair methods outlined here handle the rest. Keep a small collection of salvaged springs and basic tools in your repair kit—you’ll be amazed how often these skills prove valuable around the house. Mastering how to fix battery holder spring issues saves money, reduces electronic waste, and gives you the satisfaction of extending your devices’ lifespans through simple, effective repairs.