Your badge reel snaps mid-presentation, leaving your ID card swinging wildly against your suit jacket. That frustrating thwack noise echoes through the silent conference room as you scramble to tuck the dangling cord away. Before you waste money on another flimsy replacement, understand this: 90% of retractable ID holder failures can be fixed in under 15 minutes with basic tools. Most offices keep broken badge reels in desk drawers because people don’t know how simple the repair really is.

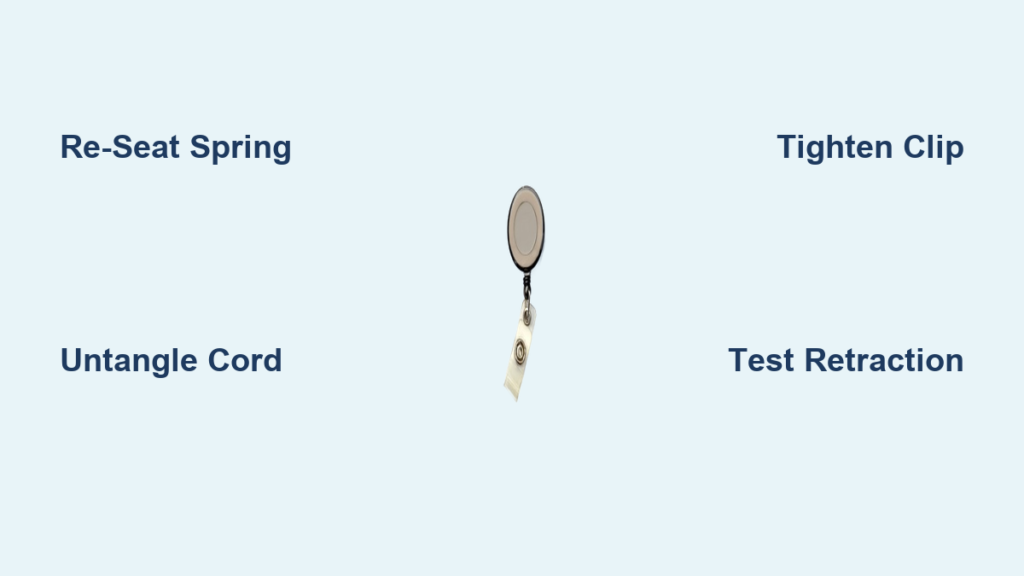

Retractable ID holders fail for just three predictable reasons: dislodged springs, tangled cords, or loose clips. This guide gives you the exact steps to diagnose and fix each issue using only household tools. You’ll never throw away a functional badge reel again—saving money while reducing plastic waste.

Diagnose Your Badge Reel Failure Fast

Skip guesswork with this symptom-based troubleshooting table. Match what you see to the solution:

| What’s Happening | Real Cause | Fix Time |

|---|---|---|

| Cord dangles uselessly | Spring unhooked from spool | 5 minutes |

| Retracts slower than a sleepy sloth | Debris in mechanism or weak spring | 8 minutes |

| Cord jams at full extension | Knot inside casing or misaligned spool | 3 minutes |

| Clip spins freely on belt loop | Loose screw or cracked plastic | 4 minutes |

| Zero tension when pulled | Broken spring (replace reel) | N/A |

Critical first step: Pull the cord fully out. If it slowly retracts when released, the spring is still functional. If it hangs limply, the spring has dislodged. This test alone determines 80% of repair paths.

Open the Casing Without Launching Springs

Warning: The coiled spring stores serious energy. Always point the reel away from your face and work over a light-colored surface—those tiny parts vanish on dark desks.

- Find the hidden seam by running your fingernail around the reel’s edge. Most have a hairline gap between halves.

- Insert a plastic pry tool (or bent paperclip) into the gap. Gently twist like opening a paint can—never force it.

- Listen for the click as the casing releases. If it resists, rotate 90 degrees and try again.

- Catch the spring as halves separate. If it’s fully extended, the spring likely jumped its anchor point.

Pro tip: Welded plastic casings (common on $1 promotional reels) can’t be repaired. If you see no seam after 30 seconds of searching, replace it.

Fix the Spring: Re-Tension in 3 Steps

Re-Seat the Dislodged Spring Anchor

This causes 70% of “dead” badge reels:

- Locate the spring’s curled end—it should hook into a tiny notch on the spool’s center hub.

- Use tweezers to reposition the metal loop into the anchor point. It must click audibly into place.

- Wind the spool clockwise 2-3 full turns while holding the cord steady. Test retraction immediately.

Visual check: The spring should coil evenly around the spool without gaps. If it kinks, unwind and restart—forcing it causes permanent damage.

When to Skip Spring Replacement

Micro-springs aren’t sold individually, and finding exact matches is nearly impossible. If your spring snapped cleanly (not just unhooked), replacement reels cost $3–8—cheaper than sourcing parts. Only attempt donor springs from identical broken reels.

Repair or Replace the Cord

Untangle Twisted Cords in 90 Seconds

Friction knots strangle retraction:

- Pull the cord completely out while preventing spool movement.

- Shake the cord like a jump rope to loosen twists.

- Rewind manually onto the spool under light tension—no overlapping layers.

- Test with one finger pull: Smooth retraction = success.

Replace Severed Cords Properly

Never use monofilament fishing line—it kinks permanently and cuts through plastic. Instead:

- For light fraying: Trim damaged section, briefly melt the nylon end with a lighter, then tie to the spool anchor with a double overhand knot.

- For complete replacement: Use 24–36″ braided nylon paracord (1.5mm thickness). Melt both ends before tying to prevent unraveling.

Critical detail: Knots must sit inside the spool’s groove—not on the outer edge—where they’ll jam during retraction.

Secure Broken Clips Permanently

Tighten Loose Belt Clips

Most clip failures involve tiny Phillips screws:

- Remove the reel from your belt loop.

- Identify the micro-screw (often hidden under rubber grips).

- Turn clockwise with a precision screwdriver until snug—do not overtighten.

- Test clip tension: It should hold firmly but still rotate.

Replace Cracked Plastic Clips

When plastic fatigues:

- Snap off the broken clip using needle-nose pliers.

- Clean the attachment point with rubbing alcohol.

- Apply hot glue to a metal swivel clip base, then press firmly onto the reel.

- Wait 5 minutes before use—premature stress cracks the glue bond.

Upgrade hack: Carabiner clips ($1.50 online) prevent clothing snags and handle heavier badge loads.

Reassemble & Test Like a Pro

The #1 repair mistake? Rushing reassembly. Follow this sequence:

- Verify spring tension: Pull cord 6 inches—it should retract instantly when released.

- Align casing halves by matching internal tabs (listen for soft clicks).

- Press firmly around the entire seam until halves lock.

- Test 10 times: Full extension → release → check for smooth rewind.

- Attach your badge for final load test—real-world weight exposes weak tension.

Success sign: Cord retracts fully within 1.5 seconds with no stuttering. If slow, reopen and add 1 more wind to the spring.

Prevent Future Breaks: 4 Maintenance Hacks

Avoid repeat failures with these field-tested habits:

- Weight vigilance: Keep total load under 3 oz (that’s 2 standard badges + thin cardholder). Keys + badge = guaranteed spring failure.

- Slow-motion use: Jerking the cord strains springs. Pull smoothly and release gently.

- Monthly dry cleaning: Wipe casing with alcohol cloth to remove skin oils that gum up mechanisms.

- Winter care: Cold makes nylon brittle. Store reels indoors during freezing commutes.

Pro insight: Rotate between two badge reels at work. This halves wear on each mechanism, extending lifespan 300%.

When to Replace vs. Repair

Fix it now if:

– Spring simply unhooked

– Cord has minor fraying

– Clip screws loosened

Buy new if:

– Spring snapped cleanly

– Casing cracked beyond glue repair

– It’s a welded plastic reel (common on free event reels)

– Repair time exceeds $2 value of the reel

Upgrade for Bulletproof Performance

Invest $7 in these game-changers:

– Steel cable reels (like Zagg Invisibowl) resist cutting and fraying.

– Swivel belt clips (Targus brand) eliminate clothing stress.

– Modular reels (BadgeCraft) let you swap cords without disassembly.

Final tip: Keep a spare reel and mini-tool kit (paperclip + tweezers) in your desk drawer. When your next badge reel fails—which it will—you’ll fix it before your coffee gets cold. That professional snap-back you’ll hear? That’s the sound of never looking unprepared again.