Your living room curtains suddenly droop as the bracket rips from the wall, scattering drywall dust across your rug. That frustrating thud when your tension rod crashes down in the bedroom isn’t just annoying—it’s a silent warning that your curtain holder system is failing. When curtain holders malfunction, they create eyesores, damage walls, and even pose safety risks from falling hardware. This practical guide delivers immediate solutions for every curtain holder failure type, using tools you likely already own. You’ll discover exactly which repair method works for your specific problem, how to reinforce weak points permanently, and why most failures trace back to preventable installation mistakes. Most fixes take under 45 minutes and cost less than $20.

Identify Your Curtain Holder Type

Bracket-Mounted Rod Systems

Metal or plastic brackets screwed into walls support these common systems. When brackets pull away, you’ll notice gaps between hardware and wall or visible screw holes crumbling. These failures happen when anchors strip out, screws hit hollow spots, or brackets bend under heavy fabric weight. Check for 2-4 mounting screws per bracket positioned 3-6 inches above your window frame—this reveals whether your system can handle your curtain’s actual weight.

Tension Rod Failures

Spring-loaded rods that slide down or collapse completely indicate failed tension mechanisms. These systems rely on internal springs pressing rubber end caps against walls. When springs weaken or end caps wear smooth, friction disappears. Test by gently twisting the rod—if it rotates freely without resistance, the tension mechanism needs repair or replacement.

Track System Issues

Bent aluminum tracks or stuck carriers plague ceiling- or wall-mounted track systems. Run your hand along the track to feel ridges or dents. Listen for grinding noises when opening curtains—this signals damaged carriers. Track systems distribute weight evenly but fail when mounting screws loosen or tracks warp from improper installation.

Magnetic and Adhesive Holders

Magnetic brackets detach from metal window frames when weight exceeds limits, while adhesive strips peel away from walls. Check for visible gaps between mounts and surfaces. These systems fail most often when surfaces weren’t cleaned properly before installation or when curtain weight exceeds the mount’s rating—always verify weight limits before attempting repairs.

Diagnose the Exact Problem

Visual Inspection Steps

Remove curtains and examine each mounting point under bright light. Look for telltale signs: crumbling drywall around screws, bent rod ends, or rubber end caps worn thin. Measure gaps between brackets and walls with a credit card—if it slides in easily, anchors have failed. Check all screws with a screwdriver; if they turn without tightening, the threads are stripped.

Load Testing Method

Apply 10-15 pounds of downward pressure on each bracket using a gallon jug of water. Listen carefully for creaking sounds indicating stress points. If brackets shift or walls flex, you’ve found weak spots. Test tension rods by pushing the center upward—if it slides down immediately, the spring mechanism has lost grip.

Common Failure Patterns

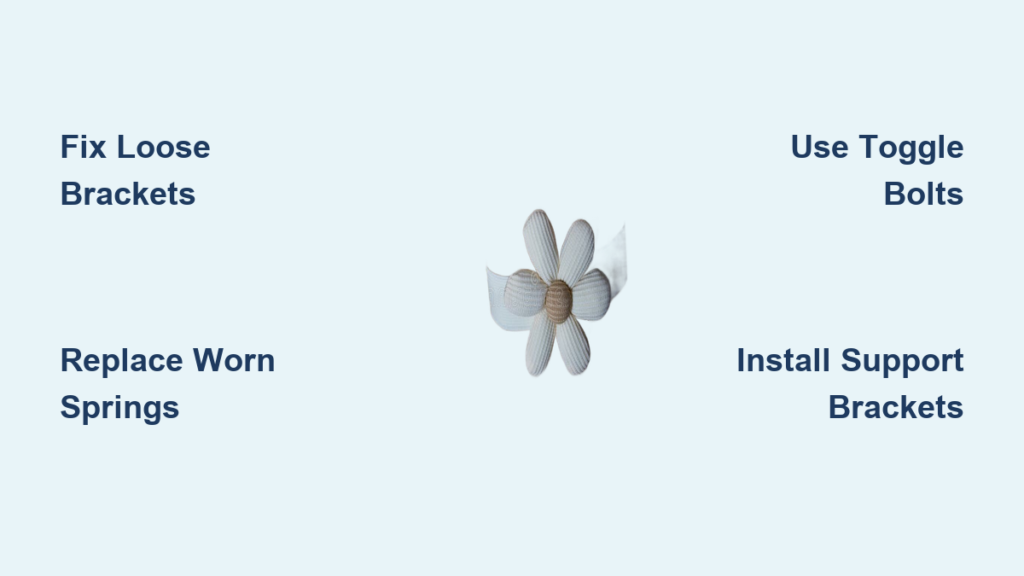

- Center sagging: Rod bends under weight (add support brackets within 24 inches)

- End brackets pulling away: Anchors failed in hollow wall (relocate to studs or use toggle bolts)

- Rod rotation: Bracket grip too loose (tighten set screws or replace worn brackets)

- Uneven hanging: Initial installation error (relevel using a 24-inch carpenter’s level)

Fix Bracket Mounting Failures

Repair Drywall Anchor Issues

When anchors pull out, remove them with needle-nose pliers. For holes larger than 1/4 inch, install toggle bolts rated for 25+ pounds: drill a 1/2-inch hole, fold wings through, and tighten until snug. Never overtighten—this crushes drywall. For heavy curtains, relocate brackets 1-2 inches left or right to hit wall studs. Use 2.5-inch #8 wood screws for maximum holding power.

Stud Mounting Technique

Mark stud centers with painter’s tape after scanning with an electronic stud finder. Pre-drill 1/8-inch pilot holes slightly smaller than your screws to prevent wood splitting. Insert screws until brackets sit flush against the wall—countersink just enough to hide screw heads without damaging brackets. Test stability by hanging curtains before final tightening.

Reinforce Weak Rod Systems

Add Support Brackets

Install center brackets every 30 inches for standard curtains or every 24 inches for blackout drapes. Use a 24-inch level to ensure perfect alignment—misaligned brackets cause rods to twist. Position new brackets so they sit 1/8 inch higher than end brackets to create slight upward tension that prevents sagging.

Rod Repair Methods

For bent metal rods, clamp ends in a padded vise and apply gradual pressure to straighten. Work in small increments, checking straightness with a level after each adjustment. Wooden rods with cracks require wood glue applied deep into splits, followed by 24 hours under clamp pressure. Sand and refinish to match before reinstalling.

Fix Tension Rod Problems

Restore Lost Tension

Disassemble the rod by unscrewing end caps and removing the internal spring. Clean all components with warm soapy water to remove built-up grime. Replace worn springs with hardware store kits matching your rod’s diameter. Reassemble with firm hand pressure, then add one quarter-turn beyond snug—over-tightening accelerates wear.

Prevent Wall Damage

Add rubber end caps to increase friction without scratching paint. If walls show compression marks from previous failures, install plastic mounting cups that create permanent contact points. For recurring issues, switch to bracket-mounted systems—tension rods shouldn’t be used for curtains exceeding 8 pounds.

Handle Specialized Situations

Heavy Curtain Solutions

Calculate total weight including fabric, linings, and hardware—then add a 100% safety margin. Install industrial brackets rated for 40+ pounds per pair using three 3-inch screws per bracket into wall studs. For windows wider than 72 inches, add two center brackets instead of one to distribute weight evenly.

Plaster Wall Repairs

Never use standard plastic anchors in brittle plaster. Install molly bolts designed for plaster: drill a hole matching the bolt size, insert the bolt until wings open behind the wall, then tighten until snug. Pre-drill slowly with a masonry bit to prevent cracking the plaster surface.

Prevent Future Failures

Monthly Maintenance Checklist

- Tighten bracket screws with a screwdriver (never a drill)

- Verify rod level using a 24-inch carpenter’s level

- Inspect curtain rings for cracks or deformation

- Test bracket stability with gentle downward pressure

Annual Hardware Assessment

Replace brackets showing hairline cracks in plastic or metal fatigue. Upgrade rods if you notice visible bowing under normal curtain weight. Install center support brackets preventively before failures occur—this takes 15 minutes and avoids costly wall repairs later.

Essential Tool Kit

- Stud finder with deep-scan mode ($15)

- 24-inch level for bracket alignment ($10)

- Drill with 1/16″ to 1/2″ bit set ($25)

- Screwdriver set including square drive bits ($12)

- 25-foot tape measure with magnetic tip ($8)

- Pencil for non-damaging wall marks ($2)

Quick Repair Decision Guide

Repair when: Single bracket fails, minor rod bending, or hardware loosens

Replace when: Multiple brackets fail, rod has kinks, or weight capacity is exceeded

Upgrade when: Adding heavier curtains, spanning wider windows, or improving functionality

Safety First

Always check for electrical wires using a stud finder’s AC detection mode before drilling near outlets. Wear safety glasses to protect against drywall dust. Never exceed weight ratings—this risks wall damage and falling hazards. For plaster walls or masonry surfaces, consult a professional to avoid structural damage.

Most curtain holder failures stem from improper initial installation rather than defective hardware. By matching your repair method to the specific failure type—whether it’s toggle bolts for hollow walls or stud-mounted brackets for heavy drapes—you’ll create a secure system that lasts years. The key is distributing weight across multiple support points: for windows wider than 60 inches, always install at least three brackets regardless of curtain weight. Start with the diagnostic steps today, and you’ll spend less time fixing fallen curtains and more time enjoying your beautifully dressed windows.