Tangled extension cords snaking across your workspace aren’t just frustrating—they’re a serious tripping hazard that damages expensive cables and wastes precious time. If you’ve ever wrestled with kinked network wires or struggled to deploy heavy-duty reels on job sites, you need a solution built for your specific cables. Learning how to make a cable reel holder transforms chaotic storage into professional-grade organization while saving hundreds compared to commercial units. This guide delivers battle-tested designs you can build in a single weekend using materials under $120, with options for stationary workshops, mobile field use, or heavy industrial applications. You’ll discover exactly how to match your holder to reel size, weight, and mobility needs—plus pro tips for avoiding common pitfalls that turn DIY projects into safety hazards.

Select Your Cable Reel Holder Design Type

Choosing the right design prevents costly rebuilds and ensures years of reliable service. Your decision hinges on three critical factors: where you’ll use it, how heavy your reels are, and whether you need to move it frequently. Ignoring these variables creates unstable holders that damage cables or collapse under load.

Build a Stationary Workshop Holder for Permanent Installations

This heavy-duty design anchors to concrete floors using 3/8″ x 3″ wedge anchors, supporting 200+ pounds of industrial cable reels. Constructed from 1.5″ x 1.5″ steel angle iron, its rigid frame eliminates wobble during cable payout. Position it in your workshop’s cable storage zone where 5-foot clearance allows full reel rotation. Critical detail: The 24″ x 18″ footprint must be 150% larger than your reel diameter—measure before cutting materials.

Create a Portable Job Site Holder Under 25 Pounds

When hauling equipment to construction sites, weight matters. This aluminum-frame design uses 1″ x 1″ extrusions and quick-release pins for breakdown in 90 seconds. Folding legs tuck into integrated storage clips, achieving compact 24″ x 18″ x 4″ dimensions that fit in truck beds. Pro tip: Taper spindle ends to 3/4″ diameter so reels slide on/off effortlessly when covered in mud or debris.

Construct an Adjustable Width Holder for Mixed Reel Sizes

Handle everything from 6-inch network spools to 48-inch industrial reels with sliding steel supports. Threaded rod turnbuckles let you dial width precisely between 6-48 inches, while 3″ industrial casters rated for 200 pounds each handle uneven terrain. Warning: Always lock adjustment pins after setting width—loose pins cause reels to shift during payout, creating dangerous cable snags.

Calculate Your Exact Load Requirements

Underestimating weight capacity is the #1 cause of DIY holder failures. A holder built for household extension cords (5-50 lbs) will buckle under industrial cable reels exceeding 200 pounds. Dynamic forces during cable deployment multiply static loads by 25%, making precise calculations non-negotiable.

Determine True Weight Capacity Needs

Start by weighing your heaviest loaded reel—don’t guess. Add 25% for dynamic forces during payout (e.g., a 120-pound reel needs 150-pound capacity). For safety, design for 125% of this total (187.5 pounds in this case). Key insight: Industrial reels with thick-gauge cable often weigh 300+ pounds—use dual pillow block bearings and 1″ spindle rods for these applications.

Match Holder Dimensions to Reel Sizes

Measure your largest reel’s diameter and width before finalizing plans:

– Small reels (6-12″ dia): Require 8-10″ spindle length

– Medium reels (12-24″ dia): Need 12-16″ spindle clearance

– Large reels (24-48″ dia): Demand 18-24″ spindle span

Critical mistake to avoid: Building spindle supports too close together causes reel binding. Always add 2 inches to your reel’s width measurement for smooth operation.

Choose Steel, Wood, or Aluminum Construction Materials

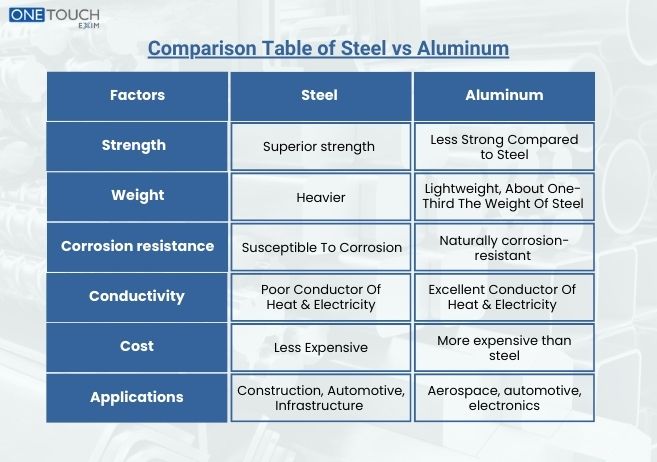

Material selection impacts cost, weight, and longevity. Steel offers maximum strength but requires corrosion protection. Wood cuts costs by 50% for light-duty use but fails with heavy reels. Aluminum balances portability and durability for field applications.

Build with Steel for Heavy-Duty Applications

Use 1.5″ x 1.5″ x 1/8″ angle iron for main frames supporting reels over 100 pounds. Schedule 40 pipe (1″ OD) creates unbreakable spindles, while 1/4″ flat bar mounting plates prevent bearing pull-through. Pro tip: Zinc-plated Grade 5 bolts resist rust better than standard hardware—never use drywall screws in structural joints.

Opt for Wood Construction to Save $40+

3/4″ exterior plywood bases with 4×4 legs work for reels under 75 pounds. Hardwood dowels (1.5-2″ diameter) serve as spindles, but reinforce with steel sleeves where bearings mount. Warning: Avoid pine or spruce—they compress under load, causing reel wobble. Always seal wood with marine varnish for moisture resistance.

Build a Stationary Workshop Holder in 5 Steps

This $85 design handles 150-pound reels using basic welding skills. Complete it in 4 hours with common workshop tools.

Cut and Weld the Steel Frame

- Cut two 24″ pieces and two 18″ pieces from 1.5″ angle iron

- Tack-weld into a rectangle, checking squareness with a combination square

- Weld 4″ x 2″ x 1/4″ flat bar mounting plates 16″ apart on vertical sides

- Drill precise 1″ holes through plates at 12″ height using a drill press

- Weld frame permanently—no bolts needed for stationary units

Install Bearings and Spindle

Press 1″ bore pillow block bearings into mounting plates. Insert 1″ diameter steel rod through bearings, securing with retaining collars on both ends. Critical test: Rotate spindle by hand before loading—binding indicates misaligned bearings. Apply lithium grease to bearing races now to prevent premature wear.

Create an Adjustable Mobile Holder for Field Use

This design handles reels from 6-48 inches wide while rolling across rough terrain. Total build time: 6 hours.

Build the Sliding Width Mechanism

Nest 1.25″ square tubing inside 1.5″ tubing for adjustable arms. Drill 3/8″ holes every 2 inches along outer tubes for locking pins. Install 1/2″ threaded rod with turnbuckle between arms—turning the turnbuckle moves arms simultaneously for perfect alignment. Pro tip: File locking pin holes slightly oversized so they work when coated in job site dirt.

Add Industrial Casters for Stability

Mount 3″ casters with 200-pound capacity at all four corners. Position wheels so the frame sits 4″ above ground—lower heights cause snagging on debris. Non-negotiable: Install wheel locks on all casters. Test mobility by loading with 125% of rated weight and pushing across gravel.

Troubleshoot Common Cable Reel Holder Failures

Even well-built holders develop issues. Address these problems immediately to prevent cable damage or safety hazards.

Fix Grinding Bearings Before They Destroy Your Holder

Grinding noise means contaminated or misaligned bearings. Shut down immediately—continued use damages spindle rods. Remove bearings, clean with degreaser, and repack with lithium grease. If noise persists, replace bearings; never run a holder with faulty bearings. Warning sign: Spindle wobble exceeding 1/8 inch indicates bent rods—replace immediately.

Stop Cable Binding During Deployment

Binding occurs when cable guides misalign with reel flanges. Adjust nylon guide blocks so cables feed straight onto the reel without side pressure. For severe cases, add UHMW plastic rollers at 45-degree angles to redirect cable paths. Pro fix: Apply silicone lubricant to cable guides—never use oil, which attracts dust.

Optimize Material Costs Without Sacrificing Safety

Build a professional holder for $85-$120 by smart sourcing—no compromises on critical components.

Slash Costs 30% with Strategic Salvaging

Scavenge bed frame angle iron (1.5″ x 1.5″) from junkyards—free and pre-cut to length. Repurpose trailer axles as ready-made spindles with bearings already installed. Savings tip: Buy pillow block bearings in bulk packs (4+) online—they cost 40% less per unit.

Prioritize Budget Spending on Critical Components

Never skimp on:

– Bearings (use sealed industrial-grade)

– Spindle material (solid steel rod only)

– Structural welds (no bolt-only connections for heavy reels)

Save on non-critical areas: Use leftover exterior paint instead of powder coating, or opt for basic casters on stationary units.

Your custom cable reel holder pays for itself in weeks through saved time and extended cable life. Start with the stationary workshop design if you’re new to metalworking—it’s the most forgiving build while handling 90% of home and prosumer needs. Within a year, you’ll wonder how you ever managed cables without it. For your next build, add the adjustable width feature using the sliding mechanism described—it transforms one holder into a system that handles every reel in your inventory. Always perform weekly visual inspections: check for loose fasteners, bearing noise, and cable wear patterns. Properly maintained, these holders deliver decades of service while keeping your workspace safe and professional.

Final Note: Always wear cut-resistant gloves when handling steel edges and safety glasses during assembly. Test new holders with 50% load first, gradually increasing to rated capacity. For electrical cable reels, add copper grounding braid between frame and spindle to prevent static discharge.